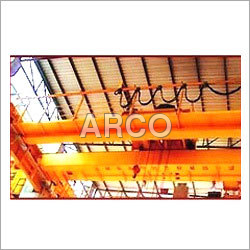

35T - Double Girder EOT Overhead Crane

35T - Double Girder EOT Overhead Crane Specification

- Feature

- Hydraulic Crane, Portal Crane

- Usage

- Industrial

- Material

- Mild Steel

- Crane Type

- Girder

- Size

- Standard

- Application

- Factory, Construction

- Color

- Yellow

- Control Type

- Cabin

- Warranty

- 1 Year

35T - Double Girder EOT Overhead Crane Trade Information

- Minimum Order Quantity

- 1 Number

- Supply Ability

- 1000 Per Month

- Delivery Time

- 7 Days

About 35T - Double Girder EOT Overhead Crane

Reliable Heavy Lifting Solution

This 35T Double Girder EOT Overhead Crane is engineered for robust industrial applications, ensuring seamless lifting and material handling. The combination of girder design and hydraulic features guarantees consistent performance in factories and construction environments. Its precision control cabin ensures operator safety and precision.

Versatile Industrial Application

Designed to assist manufacturers, suppliers, service providers, and traders, this crane supports a wide array of operations including assembly, storage, and large-scale construction. Its portal crane capabilities support broader operational needs in diverse industrial workflows throughout India.

Durability Meets Efficiency

Constructed using premium mild steel and finished in high-visibility yellow, this crane is built for longevity. With simple maintenance and superior load-bearing capacity, it upholds efficiency, reduces downtime, and meets the demanding needs of modern industry with a 1-year warranty for added peace of mind.

FAQs of 35T - Double Girder EOT Overhead Crane:

Q: How is the 35T Double Girder EOT Overhead Crane controlled?

A: This crane is operated using a dedicated cabin control system, providing the operator with a secure and clear view during heavy lifting routines. The cabin design enhances safety and allows for precise handling of loads.Q: What industries can benefit from using this overhead crane?

A: The crane is ideal for factories and construction sites. It also benefits manufacturers, suppliers, service providers, distributors, fabricators, producers, and traders engaged in heavy-duty material handling across industrial environments.Q: When should I perform maintenance on the crane?

A: Routine inspections and maintenance should be conducted as per the manufacturers guidelines, typically every few months or after periods of intense operation, to ensure safety and optimal performance.Q: Where can this crane be installed and used?

A: It is suitable for installation in industrial settings such as manufacturing plants, warehouses, and construction sites across India. Its standard size supports versatile deployments based on operational needs.Q: What is the warranty period for this crane?

A: The 35T Double Girder EOT Overhead Crane comes with a 1-year warranty, covering manufacturing defects and ensuring dependable performance during its initial operating period.Q: How does the hydraulic feature enhance crane performance?

A: The integrated hydraulic system provides smoother and more efficient lifting and movement of heavy materials, increasing productivity and reducing the physical strain on both equipment and operators.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Double Girder E.O.T Cranes Category

Double Girder E.O.T Cranes

Price Range 25000.00 - 50000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Crane Type : Bridge

Control Type : Remote Control

Material : Stainless steel and Cast Iron

Application : Ship Building

Double Girder Overhead Cranes

Price Range 25000.00 - 50000.00 INR

Minimum Order Quantity : 1 , , Number

Crane Type : Bridge

Control Type : Remote Control

Material : Metal

Application : Ship Building, Construction

Double Girder Overhead Crane

Price Range 25000.00 - 50000.00 INR / Unit

Minimum Order Quantity : 1 , , Unit

Crane Type : Girder

Control Type : Remote Control

Material : Metal

Application : Railway, Warehouse, Storage Yard

Double Girder Crane for Transformer Industry

Price Range 25000.00 - 50000.00 INR

Minimum Order Quantity : 1 , , Unit

Crane Type : Tower Mounted

Control Type : Cabin

Material : Metal

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS